Nation to promote use of recycling systems and renewable resources

To further boost the development of China's circular economy, the government set up a target to raise the country's resource-utilization efficiency by 15 percent compared with the 2010 level, the State Council, or China's cabinet, said on Tuesday.

The move means that the circular economic industry will reach an overall output worth 1.8 trillion yuan ($290 billion) by the end of the 12th Five-Year-Plan (2011-15), according to a plan released on the government's website.

|

|

|

Workers at a construction site in Shangsi county in the Guangxi Zhuang autonomous region collect used steel rods, which will be straightened for reuse. [Photo/China Daily]? |

The plan said the country will boost the circular economy in the agricultural and industrial sectors by improving recycling systems, promoting the use of renewable resources, developing re-manufacturing and applying "green" construction and transportation methods.

According to the plan, the steel industry, which has been considered a polluting sector for years, will have to use less than 580 kg of standard coal for each ton of steel produced.

"The target is reachable if the companies try hard," said Xu Xiangchun, information director at mysteel.com, a steel industry website and consulting firm.

In 2011, major steel companies used about 602 kg of coal for each ton of steel produced, he added.

"Chinese steel producers' energy consumption is about 15 percent more than the level of developed countries with advanced technologies," Xu said. "However, we have made big progress in terms of water consumption for steel production."

Under the plan, the steel industry will have to reduce its water consumption to 4 cubic meters for each ton of steel produced.

Xu said that many Chinese steel companies have already achieved 3.88 cu m of water use for each ton of steel produced in 2011.

The plan also stipulates that by the end of 2015, annual scrap steel recycling will have to be at about 130 million metric tons.

Analysts said that this goal will not be that easy to achieve.

"The utilization of scrap steel depends on the quantity of scrap steel the country produces every year," Xu said. "Although China's auto sales have been increasing rapidly, auto recycling still takes up only a small share of the total figure."

He added that construction scrap steel, which accounts for about 30 percent of the total, is the major contributor for the steel recycling industry, but the life cycle of such steel products is relatively long - between 50 to 100 years.

Also according to the plan, coal bed methane - a growing type of clean energy - needs to achieve an extraction efficiency of 60 percent and an installed generation capacity of more than 2.85 million kilowatts by the end of 2015.

The Jincheng Anthracite Mining Group, the largest coal bed methane producer by output, achieved an extraction efficiency above 60 percent in 2012, said Ding Yuefeng, a company spokesperson.

The company's coal bed methane output accounted for about 52 percent of the country's total output.

However, the majority of Chinese energy companies with coal bed methane businesses haven't reached that level yet.

The plan has also outlined resource-utilization efficiency targets for many other industries by 2015.

For instance, the crude oil refining industry will have to reduce its energy consumption to no more than 86 kg of standard coal for each ton of oil produced, and reduce its water usage by 30 percent compared with the 2010 levels.

In the coal-fired power generation industry, the government requires companies to reduce the average energy consumption to 325 grams for each kW of electricity generated by 2015.

dujuan@chinadaily.com.cn

'Cat model' to dazzle Shanghai auto show 2013

'Cat model' to dazzle Shanghai auto show 2013

Models at Tokyo modified car show

Models at Tokyo modified car show

Shanghai Fashion Week focuses on domestic brands

Shanghai Fashion Week focuses on domestic brands

Angel-dress models at Shandong auto show

Angel-dress models at Shandong auto show

Safe and Sound

Safe and Sound

Theater firms scramble for managers

Theater firms scramble for managers

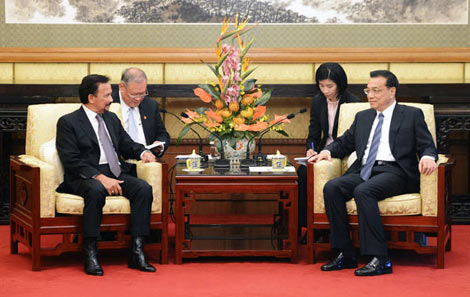

Premier pledges closer ties with Brunei

Premier pledges closer ties with Brunei

Volkswagen's all-new GTI at New York auto show

Volkswagen's all-new GTI at New York auto show